PAVER BRICK

Paver block or Paving block is one of the most popular flexible surface treatment options for exterior pavement applications. These blocks are aesthetically pleasing, comfortable to walk on, extremely durable, and easy to maintain.

STONE FINISH

Red, Yellow, Gray, Black

SIZE: 60MM

MUSHROOM

Red, Yellow, Gray, Black

SIZE: 60MM

JOHNSON

Red, Yellow, Gray, Black

SIZE: 60MM

ZIG ZAG

Red, Yellow, Gray, Black

SIZE: 60MM & 80MM

COSMIC

Red, Yellow, Gray, Black

SIZE: 60MM

BRICK PATTERN

Red, Yellow, Gray, Black

SIZE: 60MM

OCTAGON

Red, Yellow, Gray, Black

SIZE: 60MM

FLYASH BRICK

ADVANTAGES:

- Eco Friendly

- Even Shape

- Uniform Colour

- Sharp Edges

- Need Less Mortar

TECHNICAL SPECIFICATIONS

- DENSITY: 1700-1850 KG

- COMPRESSIVE: 8MPa

- WATER ABSORPTION: 6-12%

- TERMAL CONDUCTIVITY: 0.90-1.05 w/SqmC

6 inch

4 inch

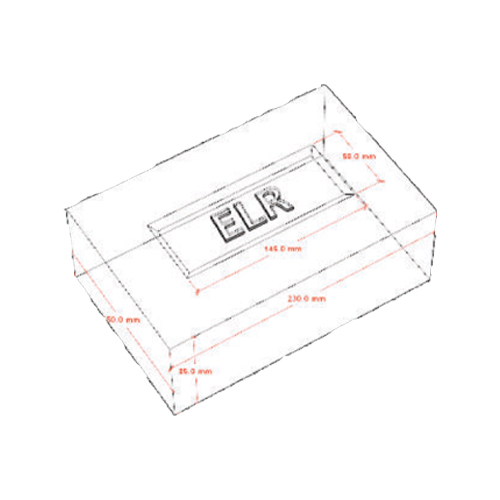

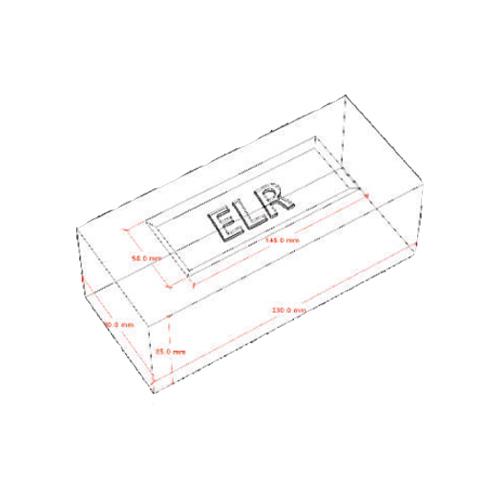

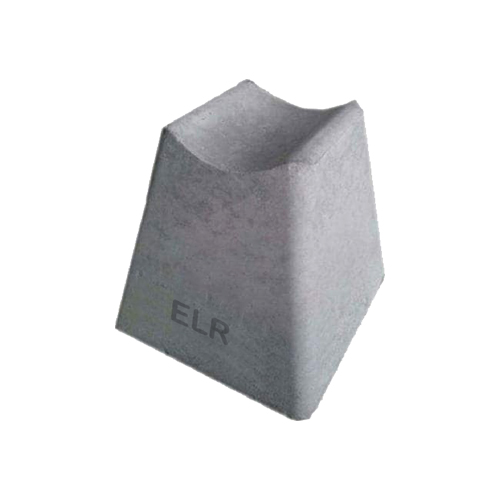

COVER BLOCK

The precast concrete product, which is used to provide the necessary covers or spacing for the reinforcement bars from the formwork, in all RCC structures like slab, colum, beam, footing, etc. are called concrete cover blocks or concrete spacer blocks. They are available in a variety of shapes and size as per their specific use.

COVER BLOCKS

SIZE: 20/25/30MM

COVER BLOCKS

SIZE: 20/25/40/50MM

STANDBY

S- 50MM / S- 75MM

WHEELS SPACER

R- 25MM

WHEELS SPACER

R- 30MM / R- 40MM

KERB STONE

A Kerbstone is a concrete stone or a concrete solid which is fixed end to end with other solids to form a Kerb. It makes the drivers conscious of the pavements and greenery areas in demarcating roads, streets, car parks etc. It makes a clear cut view of the carriageway.

KERB STONE

SIZE:

300MM X 300MM X 100MM

KERB STONE

SIZE:

300MM X 600MM X 100MM

KERB STONE

SIZE:

450MM X 300MM X 100MM

KERB STONE

SIZE:

450MM X 300MM X 150MM

KERB STONE

SIZE:

300MM X 450MM X 100MM

KERB STONE

SIZE:

300MM X 450MM X 150MM

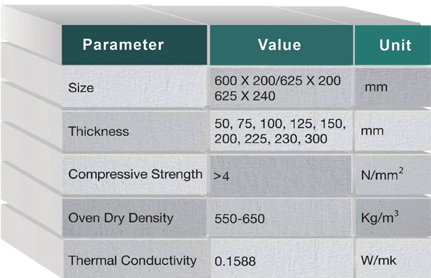

AAC BLOCK

No matter what your requirement is, you will find a ELR AAC? that suits you.

ADVANTAGES:

ELR AAC is one fifth the weight of concrete and is produced in easily handled sizes. It reduces dead weight of a structure, and consequently consumption and investment in steel and concrete.

Made of fly ash mixed with readily available raw materials like cement, lime, water and an aerating agent which are autoclaved to give a superior alternative to red clay bricks and a highly durable & energy efficient building material.

Across residential, commercial and industrial buildings ELR AAC can be easily cut, drilled, nailed, grooved, screwed,milled crafted and shaped with common hand tools and is readily adaptable to any style of architecture. It is available in many sizes and thicknesses - ranging from 75 mm to 300 mm.

ELR AAC withstands harsh climatic conditions and remains unaffected under normal atmospheric conditions throughat years.

Being 8 times the size of a clay brick, ELR AAC wall construction involves 1/3 the joints, thus an overall mortar saving of up to 66%. Reduction in steel is up to 27% and cement up to 20%.

GREEN ALTERNATIVE

As compared to conventional bricks ELR AAC decreases over 50% greenhouse radiation & integrated energy and utilizes at least 70% environmental waste.

ELR AAC's high surface mass coupled with the mechanical vibration energy damping within its porous structure produces construction material with exceptional sound insulation properties.

ELR AAC is an inorganic and incombustible building material with a melting point of over 1600 C.

Due to unique chemical structure, ELR AAC provides superior thermal insulation than conventional masonry.

It is impossible for insects and rodents to inhabit in ELR AAC due to its impermeable and compact nature.

The thermal insulation characteristics of ELR AAC contribute to a pleasant interior environment leading to greater energy savings in air conditioning.

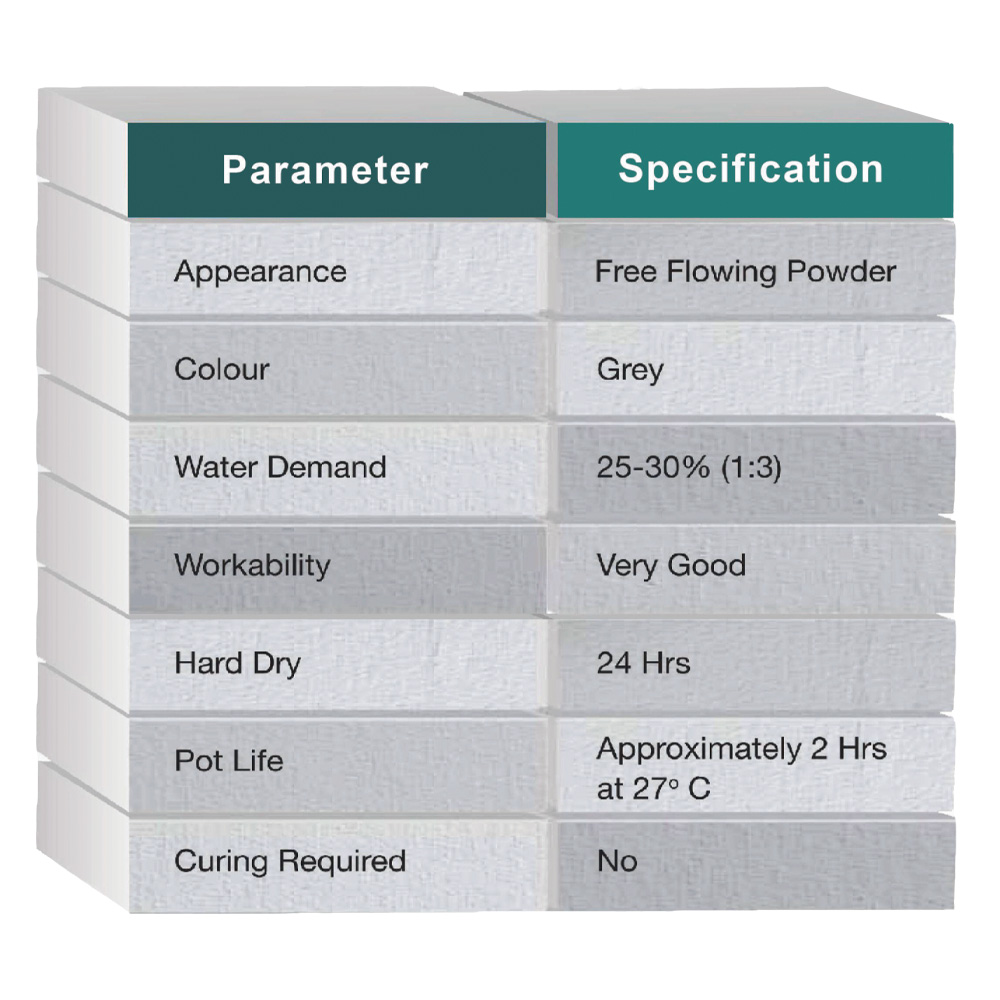

BOCK JOINTING MORTER

ELR BBM block binding mortar is a thin-joint, high strength adhesive for quick and firm construction of AAC blocks. It is manufactured through a PLC Controlled computerised process from cement and graded natural sand blended with polymer to impart high strength and water retention properties. Controlled manufacturing processes ensures consistent quality output as per specifications across batches. ELR BBM is delivered to the construction site in bags. Only water needs to be added.

ADVANTAGES:

- Faster application- ELR BBM allows for continuous laying and takes less time for setting than conventional mortar.

- Economical- Reduced construction timelines by using ELR BBM leads to reduction in direct cost of labour and overhead costs.

- No Shrinkage cracks.

- Consistent Quality- Computerized manufacturing process in con- trolled environmental conditions ensures there is minimum human intervention to provide consistent output quality across batches.

- Improved build accuracy of finished walls.

- 100% natural sand for best coverage results.

- ELR BBM provides for better adhesion, stability and durability.

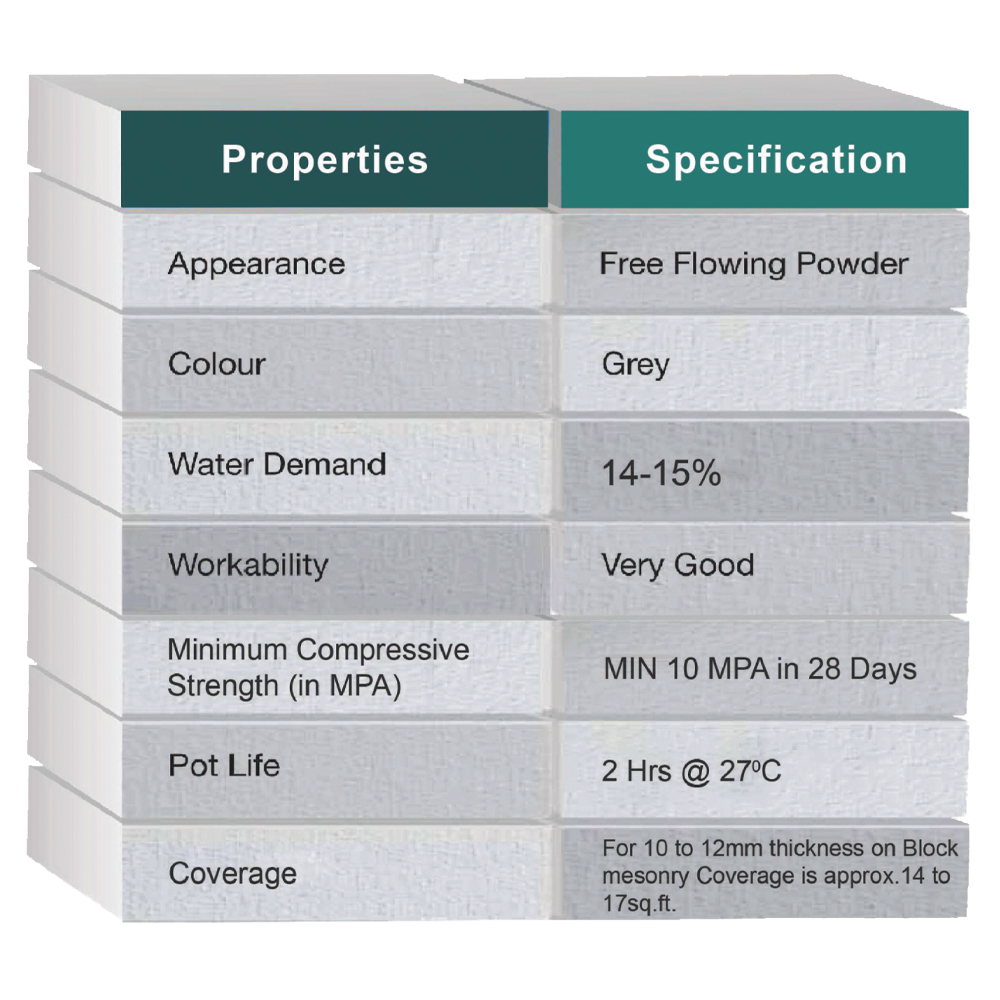

READY MIX PLASTER

ELR Duroplast is a convenient easy-to-use plaster which is not only stronger than traditional plastering but also looks nice & binds better.

It is manufactured using high quality well graded sand, special binders, cement and polymers in a controlled environment to give you highly durable and impermeable water tight plastering solution. It can be used effectively on brick, block, stone masonry works, concrete surfaces in both inner and outer walls.

ADVANTAGES:

- Smooth Finish

- Frequent watering (curing)not required

- Time Saving and less rebound reducing material wastage

- Uses 100% natural sand free from silt

- Easy to use

- Impermeable

- Reduces chances of developing cracks on the surface